I have been doing this for a long time and just when I think I have seen it all, someone comes in with the funkiest exhaust system. In this article I want to explain what is going on with your exhaust system and what effect it has on the motor. Then you can decide which exhaust system would work best for you. There are many to choose from, some are fantastic and some are just a joke.This article will be directed at engines that are not blown or turboed.

A good exhaust system can really help an engine and a bad one can really hurt the potential of a good motor. What we want is equal length pipe going into a nice merge. That is where four pipes would merge into one. Think about exhaust pulses working like a train. We fire on one cylinder and as the tail of that pulse is leaving the merge, the head of the next cylinder can hitch a ride on the tail of the previous cylinder that fired. This helps in getting rid of the exhaust. In other words we want that train to leave in an efficient manner and not have a train wreck or ever turn around. Make sense?

Lets look at the stock exhaust. You have four unequal length pipes shoved in a can with no merge. Oh boy, that’s a train wreck. You are basically throwing a bunch of trains in a can and only giving it one or two places to get out. You have trains looking for exists. You can have some trains trying trying to go back up another cylinder until that valve opens and the conductor says hey you can't come in there we have another train leaving. If you get enough trains in the can they will eventually find their way out. So by that you can see that the stock system sucks as far as efficiency goes. That goes for any exhaust system that has unequal length pipe and stuffs into a can without a merge. I hope this is starting to make sense.

What about two headers, one for each side? First we need to look at is the firing order. It’s 1,4,3,2. So what? Well lets start with number 4 cylinder instead of cylinder number 1. Then the order would be 4,3,2,1. Ok still, so what? Go look at your motor and point to number 4 then go 3, 2,1. Your motor is firing one side then the other. Where are we going with this? If you put a system on that has one header for one side and one for the other, then one side does not help the other out. Back to the train, we want the tail of one train to help pick up the head of the next train. Another way to look at is: instead of having a four cylinder motor, we now have two, two cylinder motors, joined by the same crankshaft. One of the worst system you could put on a motor other than stock is four individual pipes. The only way that works is if you run Nitro Methane for fuel, as the pulses are so violent.

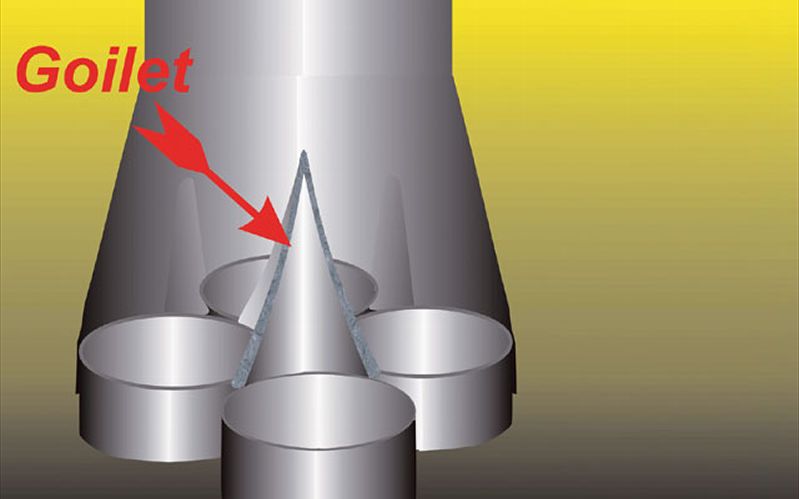

Now we know what a good system should be- Four into one merge. How do you know if you have a good one or a cheap one? Look inside the pipes where the merge is. You should see what looks like a spear head, where the four pipes have been cut and welded together. That is called a goilet. That needs to be sharp and nice. No slag or crap hanging off it. Keep in mind we want that train to run freely in the merge. No wreck due to slowing the train down.

Now the big question. What the hell does this have to do with the running of the motor? Well if you had your motor on a dyno you would see that the exhaust can and will affect the jetting. How’s that you ask? Well you have what is called overlap on your valves. That is when your intake valve is opening and your exhaust valve is closing. At some point both valves are open. Different cams can increase or decrease the length that they're both open. So think about this, the train is leaving the combustion chamber and a new load of fuel is coming in. If the train is leaving in a hurry then it will actually pull more fuel into the chamber. Ah ha, now you’re starting to get it. However, more fuel can be a good thing. More air and fuel equals more power, or at the very least more efficient. One note here: at low rpms this effect can hurt us a little in that some of our new charge of fuel can leave the chamber.

Now that brings me to mufflers and stingers. I prefer a muffler on street cars and here is why. If my exhaust system is a good one it can hurt me down low in the rpms like I just said. By having a muffler, I put a little bit of back pressure on the system. In other words I am slowing down the trains. By doing this, my fuel charge doesn’t leave the chamber at low rpms and my muffler will flow well enough at mid range to work efficiently. Now top end will suffer a little but this is a street car not a drag car.

If this was a drag car/weekend car then stinger is the way to go. I have jetted carbs on a street motor that has a stinger and it always end up with bigger jets than the same motor with a muffler. Why? Because I have to make up for that extra fuel that is being pulled out. What about header size? Well that is a long subject, but here are the basics for making that decision. What is the compression ratio? If high then a bigger system is used. What is the duration of the cam? The higher the duration of the cam the bigger the pipe needs to be. Why? Because the higher the duration is the higher the motor wants to rev. There is a lot more to it than that but that is the basic. In my opinion, a street motor with low compression (7.5 to 8.5) should have 1 3/8 to 1 ½. A motor with higher compression (9 to 11) should have 1 5/8. Anything over that compression you already know all this and can pick out what you need.