In this article I would like to talk about you guys with off road cars and your oil pressure. I am a big fan of deep sumps but on most off road cars that is not an option as it hangs down too far and will just get ripped off. So what do we do? Well I have found a couple of options, but first let’s talk about what is happening. It’s not that the motor doesn’t have any oil in it, it’s just that the oil is not at the pick up tube. In this article I can go over some parts you might think about if you’re building an off road motor or a vehicle that might have an oil starvation problem.

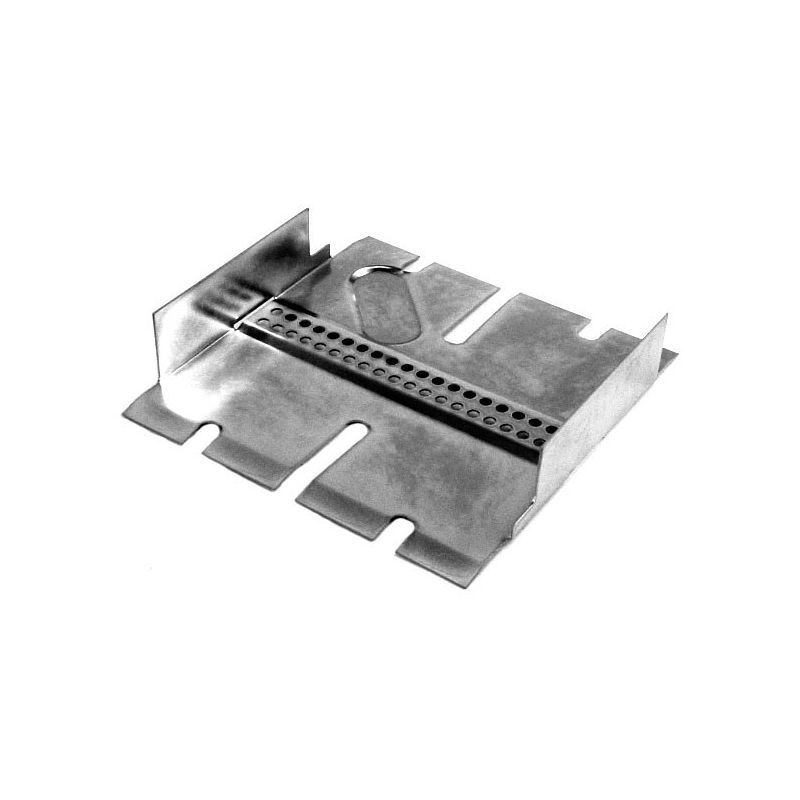

Windage Tray: This is a tray the sits in the sump area of the case, they’re cheap. There purpose is keep the oil from sloshing around and slow down the oil that is running down the push rod tubes when side hilling. Some companies sell a windage push rod tube that kind of does the same thing. If your motor is apart this is a good thing to have. If not then I don’t think it’s worth tearing the motor apart to put one in.

Super Sucker: Get your mind out of the gutter. Yes this is what it’s called. This is an extension you put on the end of your OE pick up tube and it extends the pick right down to the bottom of the block. It has to be used with an OE dual relief case pick up tube. You do not use the stock screen as it has its own screen. One major drawback with it is it does not have a drain hole. So when you want to change your oil you have to take the plate off. One trick I have done is put a drain plug in the type 3 block off plate as your case is a universal case. Even then I have to jack up the left front tire to get the oil to drain all the way out that hole. Does it work? Yes it does.

Accusump or Oil Accumulator: Now this is a good deal. What it is is a cylinder with a piston in it. The back side of the piston has a spring and in conjunction with that it has air pressure again on the back side. Here is how it works. Oil comes in at the bottom of the cylinder and hits the piston. When the pressure goes up beyond 10 lbs then the piston retracts, and stays back. If the pickup tube gets air we will have no pressure. The piston comes down in the accumulator and feeds the motor. So when you’re out jumping your car or side hilling this will make up for the seconds that the pick up tube in the block is not in oil. Also with the electric solenoid when you turn the key on the valve opens, pre oiling the motor before the starter kicks in. When you shut the ignition off, the accusump is now storing oil until the key is turned back on. Make sense? I am a huge fan of these. They cost about $460.00 by the time you by the check valve, electric solenoid and all the fittings. It can mount just about anywhere. Bad news: Other than the cost you better triple check how you have it plumbed. Getting the check valve in wrong can cost you the motor. It also requires that you have some type of external oiling on your motor as it “Ts” into the return line of your oil system. I have had a couple of racers that are hard core and are really hard on equipment. This solved our oil pressure problems. Keep in mind they had the windage tray and the super sucker. Not that you have to have those things but they did and it wasn’t enough so we put the accumulator on.

Dry Sump: This is an oiling system that pulls the oil out of the motor and puts it into a tank, then pumps out of the tank and back into the motor. Are they good? Hell yes they’re good. Here is how they work. The oil pump is multi stage. We will just discuss the two stage because the three plus stages are just more pick up or scavenge. The first stage of the oil pump picks up oil out of the motor and pumps it into a tank. The design of the tank is important as it has to keep foaming of the oil to a min. The second stage of the pump then pumps the oil out of the bottom of the tank and back to the motor. Advantages; The crank and cam do not have to swing through oil, which is a horse power gain. Having a tank full of oil ensures that we have oil to pump into the motor. Disadvantages; The multi stage pumps take more horse power to turn, so your horse power gain you just got is lost. It’s about a wash really. Being that you have a larger pump you have to run a smaller crank pulley to clear the pump. This slows down the fan. Now the biggy. They are not cheap; around a $1000.00 plus and you have to do a lot of plumbing. Again you have to map out your lines and triple check them. One wrong hose placement and you blow up the motor. Placement of the tank is important as well. It works best if level with the motor, not above it. You can mount it above the motor. but when the car sits for a period of time it can overfill the motor.

So there are three ways to help oil starvation. Myself I use the first step in most sand cars. I warn the owner of the car to watch the oil gauge when getting crazy. If he or she sees a light he or she will have to step up to the accusump. If the owner can afford it and has lots of room then I will go dry sump. Now on circle track cars I have found we have to run a dry sump and put a pick up in the right valve cover.

There you have it. If you are building an engine that might run into an oil starvation problem you should think about what is mentioned here.