In this article I will explain some of the different ways to lower the front end of your ride. Then, you can decide which way to go. Keep in mind that all of the standard air cooled VWs have a trailing arm suspension in the front, with the exception of the Vanagon. Super Beetles, 411, and 412s had strut front ends (similar to an A-arm suspension).

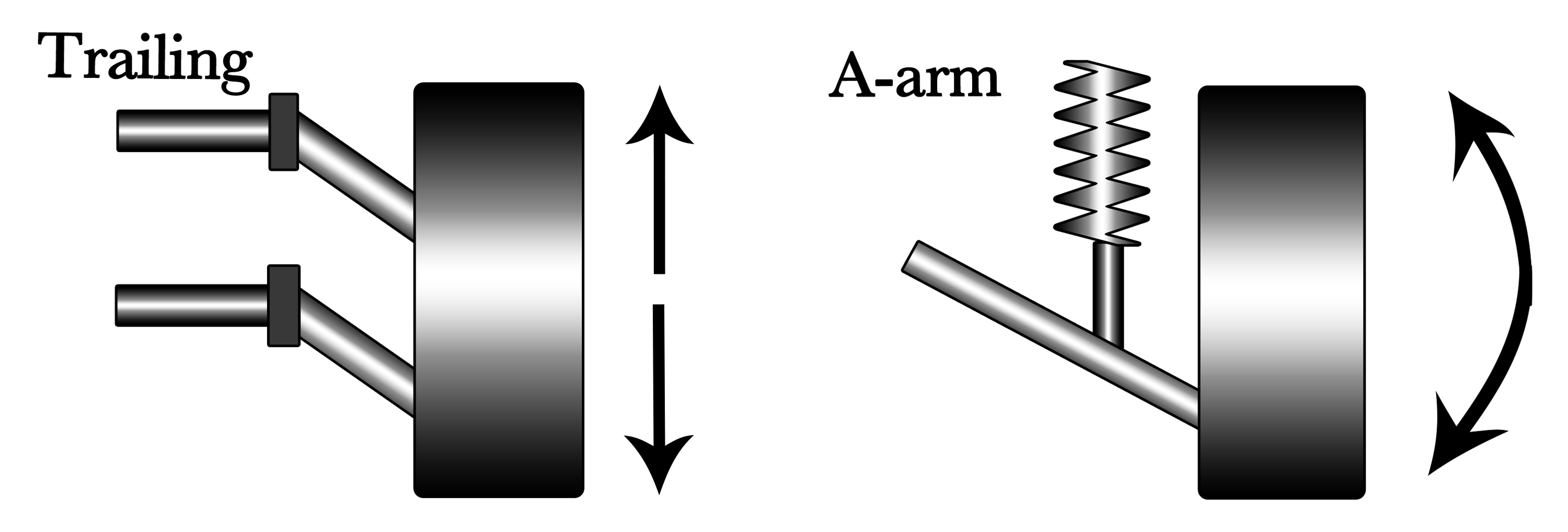

Why is this important? Trailing arm suspension has arms that point down and back. So your wheel goes up and down straight. In other words the wheel does not move in and out of the fender well like with an A-arm suspension.

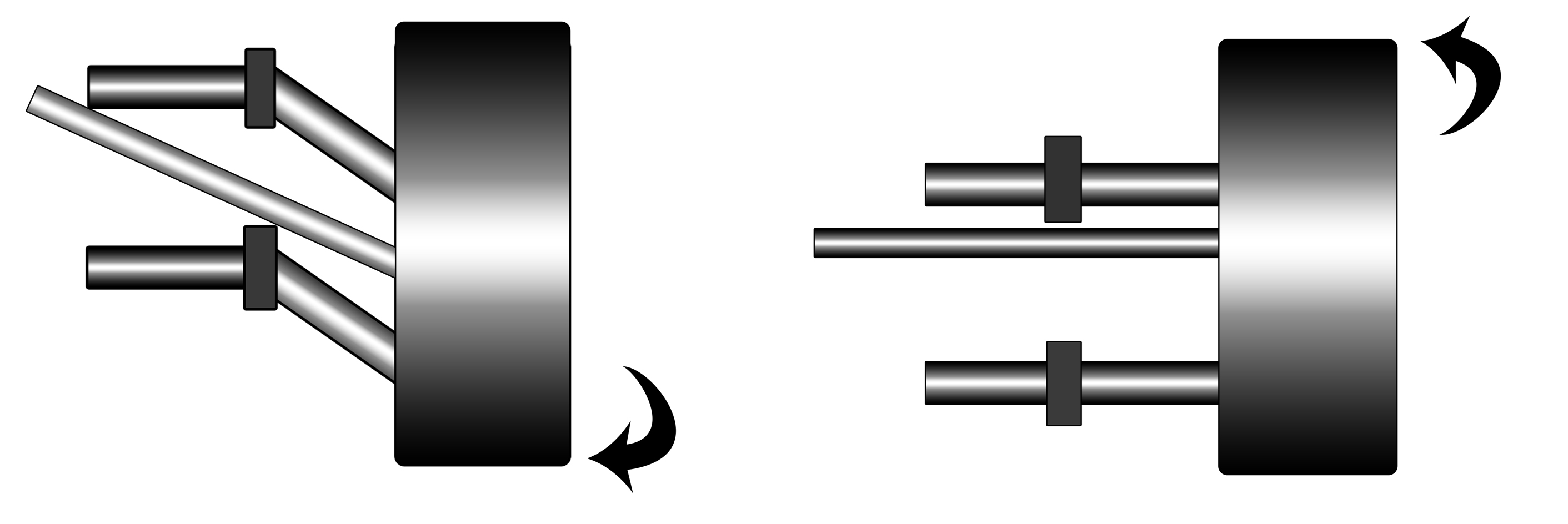

The good news about a trailing arm suspension is that when the arm is pointed down and back it absorbs the shock when you hit something like a pothole. This is why the suspension lasts so long. On an A-arm suspension, the tire has to absorb the shock as it moves straight up and down. That is why people have to replace the A-arm bushings periodically. The bad thing about trailing arm suspension is the bump steer. As the wheel goes up you gain toe in. When the tie rod is pointed down, it pulls the back of the tire in. As the arms go up, the tie rod pushes the tire in giving you toe in.

When you’re doing your alignment, it’s a good idea to set your toe in at ride height. In other words, don’t do it with the tires hanging in the air. Do it as if the car was going down the road. Here are some pictures to try and explain what’s going on.

So now you know the pros and cons on the trailing arm suspension at stock height. Here are some lowering options along with their pros and cons.

Adjustable beams for trailing arm suspension: This is where we make the spring anchors in the middle of the beam adjustable. This way of lowering a beam has been used for years. Good news is that it’s a cheap way of lowering your beam. Bad news is that if you go too low as to have the arms pointed up, your ride will be really stiff. Instead of the arm moving back and away when it goes up, it will now move forward, increasing the shock of the pot hole. Another way to explain it is; if you catch a fastball with your mitt and your mitt is traveling the same way as the ball it doesn’t hurt. If you move your mitt into the ball as it’s coming then the palm of your hand will sting. Make sense?

Lowered spindles: This is a great way to go if you want to maintain your ride because the spindle is just moved up, resulting in lowing the car and keeping the trailing arms pointed down. The good news is that you don’t have the jaw-breaking ride. The bad news is that these spindles usually push out your tires and are more expensive than the beam adjusters. Some spindles more than others. So fender clearance can be an issue. A narrowed beam is one way to solve this, but keep in mind that by shortening the length of the spindles, your ride will stiffen up.

For the best trailing arm suspension I usually do both, adjusters and lowered spindles. I will set up the adjusters on the beam to give me an inch up and the rest of the adjuster down. That way when I get it all together, if the car is to low with the adjuster at stock height I can raise it with that inch of adjustment that I put into the beam. If it’s not low enough, I can go down with the adjustment. Keeping in mind I want the arms still pointed down.

Something else to consider: If your car has four lug drums then when you buy the spindles buy the disc brake conversion. Bang for the buck hell yeah. If you have wide five then yeah you have to do some thinking about the cost. On king and link lowered spindles keep in mind most companies sell them as just the spindle. No king pins no link pins. You will need a machine shop to put this together so you can bolt things on.

For A-arm or strut front ends: On super beetles, lowered struts are the way to go. With a shorter strut insert, it will allow for shock travel. For Vanagons also, lowered struts are the way to go if you can find the kits to do it. Cutting the springs works, but keep in mind that the shock can bottom out if you take too much off. Also, getting the springs out without the proper tools is very dangerous.

So now that you know how the suspension works and what happens as they go through their travel, you can decide what is best for your ride.